Products

-

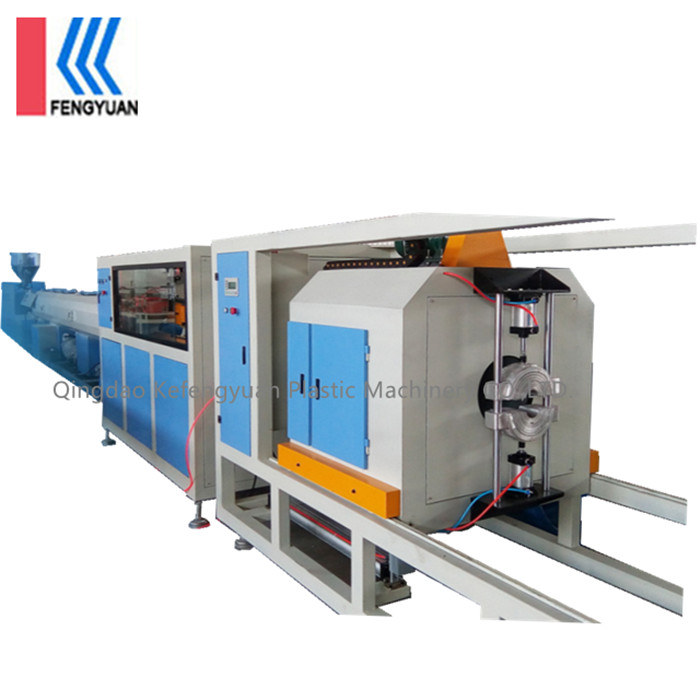

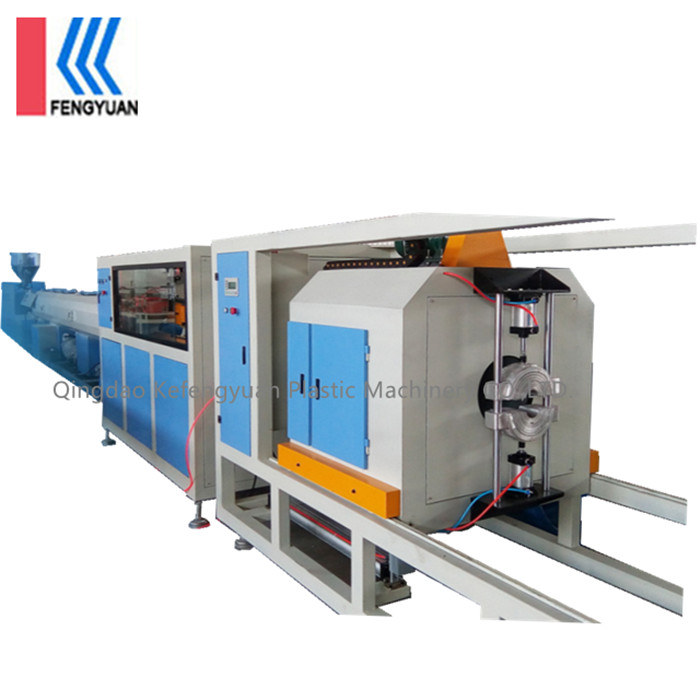

Plastic Water-Loop Granulation Line

The plastic water-loop granulation equipment produced by Kefengyuan is composed of feeder, extruder, die head, screen changer, pelletizer, centrifugal pellet dryer, vibration sieve, air suction storage bin and electric control system. The granulator can be applied to the granulation of HDPE / LDPE / PP / PET / PA and other plastics, and the output can reach 200-1200kg / h. Kefengyuan’s water loop granulation line is an ideal equipment for plastic granulation. At the same time of high output, the plastic particles produced have beautiful appearance, uniform size and are not easy to adhere. The machine has the advantages of easy operation, observation and maintenance.

-

UPVC/CPVC Pipe Production Line

The PVC extrusion line produced by kefengyuan Plastic Machinery Co., Ltd. is composed of mixer, twin-screw extruder, die, vacuum cooling water tank, inkjet printer, haul-off machine, cutter, opening extending machine and bracket. We can produce large-diameter PVC production line, PVC double pipe/four pipe production line and PVC perforated pipe production line. Our equipment has the advantages of high efficiency and energy saving, stable production and high cost performance.

-

PP/PE/PA Single Wall Corrugated Pipe Extrusion Line

The production line is applicable to the production of small-diameter (9-64mm ) single wall corrugated pipe with PP / PE / PA as raw material. The production line consists of automatic feeding & drying machine, extruder, forming machine, Winding machine and electric control system. The produced single wall corrugated pipe is formed at one time through a special mold, which can be widely used in electric conduit, automobile internal line protection pipe, washing basin drain pipe, air conditioner drain pipe, farmland concealed pipe and other fields.

-

Plastic Single/Double Shaft Shredder

Various types of plastic shredders produced by our company can effectively shred large-scale waste rubber and plastic products and wood,etc. The equipment includes the main body, control cabinet, feeding platform and can be matched with conveyor belts and storage bins according to requirements. The output can be from 400kg/h-1500kg/h. The machine is efficient and stable, with low failure rate, simple operation and easy maintenance.

-

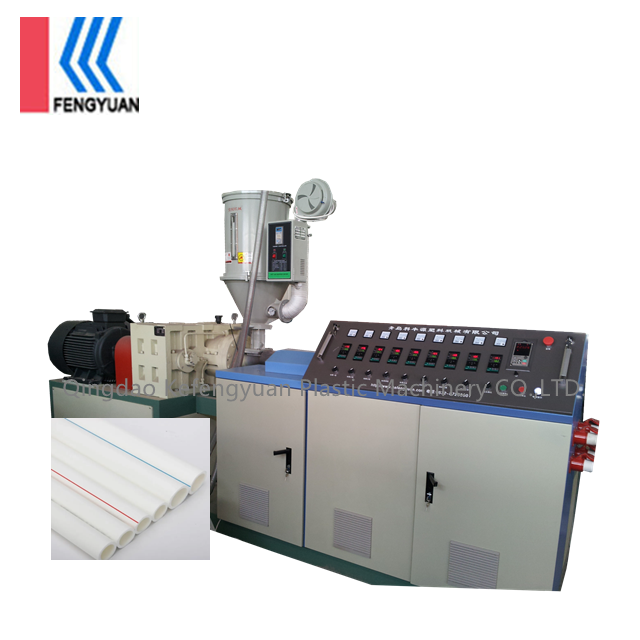

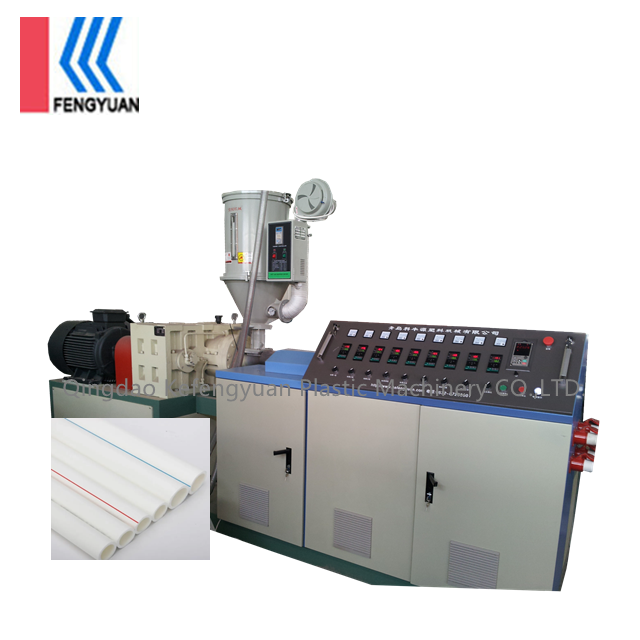

PPR/PE-RT Pipe Production Line

Kefengyuan company can provide PP-R / PE-RT single pipe production line and double pipe production line for the production demand of PPR and PERT pipes. The production line is mainly composed of automatic feeding machine, extruder, marking line extruder, die-head and mould, vacuum sizing tank, haul-off machine, cutting machine, winder and electric control system. Our machine has high output, strong stability and easy operation. PP-R and PE-RT pipes have the advantages of high dimensional accuracy, large diameter range and smooth surface and inner wall. They can be used as cold and hot water pipes in buildings, drinking water pipes, floor heating pipes, etc.

-

Plastic Welding Rod Production Line

The plastic welding rod production equipment produced by our company can be used to produce PP/PE welding rod. The plastic welding rod can be used for welding of plastic tanks and containers, welding of various pipes and plates, and leakage repair and connection of various plastic products. The production line can produce one or two plastic welding rods at the same time. The shape of plastic welding rod can be round, oval, triangle, etc. The machine has the advantages of stable operation, high output, low energy consumption and easy operation. The plastic welding rod produced by the machine has regular shape, no bubble and good quality.

-

Plastic/Wood/Rubber Crushing Line

Kefengyuan company’s crushing line is composed of shredder, conveyor belt, crusher, air suction storage bin and electric control system. The crushing unit first smashes the large materials into small pieces by the shredder, and then enters the crusher through the conveyor belt to continue crushing into smaller particles. The crushing equipment can be used to crush waste plastics, rubber, wood plastic products, etc. The maximum crushing efficiency can reach 1500 kg / h. It has the characteristics of simple operation and stable operation, which can effectively save labor cost.

-

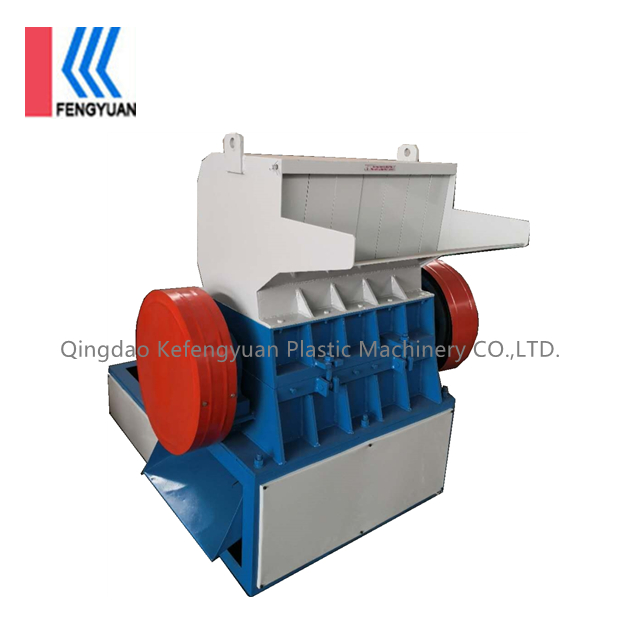

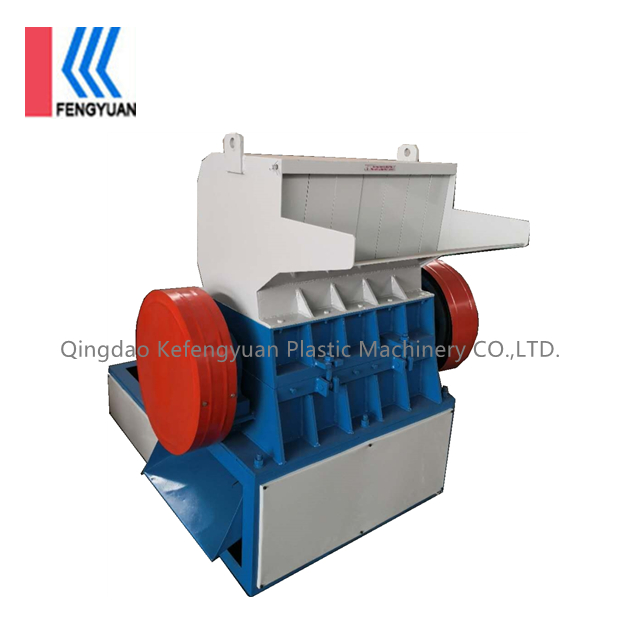

Plastic/Wood/Rubber Crushing Machine

The crusher series produced by kefengyuan plastic machinery company includes model 2232, 260, 300, 3040, 360, 380, 400, 450, 560, 600, 630, 800 and 1000 crushers. It can effectively crush plastic plates, pipes, profiles, blocks, machine head materials, rubber products, sponges, textiles and plant rhizomes. The crushing efficiency can range from 100kg / h to 1500kg / h depending on the model and crushing object. The crushing machine produced by our company has the advantages of high efficiency, durability, easy operation, strong adaptability and high cost performance.

-

HDPE hollow wall winding pipe production line

The extrusion line is mainly for producing hollow wall winding pipe. HDPE hollowness winding pipe has small masses and a low roughness coefficient, are widely used for sewerage systems, storm drains, treatment facilities and sanitation of the old pipeline, well and various sewage tanks are manufactured. Pipes with diameters from 200mm-4000mm and the stiffness classes SN 2,4,6,8,10,12,14,16. Pipe extrusion line first produces square pipes from HDPE, then with the help of a co-extruder and spiral molding machine, spirally wound onto the walls and subsequently welded together forming the pipe body. Pipe extrusion and winding system are separately controlled, can be used separately. The line energy saving, easy to transport and installation, the investment is lower, easy to maintain.

-

Soft PVC/Black Rubber Sealing Strip Production Line

The sealing strip production equipment produced by our company can be used to produce soft PVC sealing strips / black rubber sealing strips of various sizes and shapes. It can be used as automobile door and window sealing strip, aluminum alloy door and window sealing strip, refrigerator, cabinet sealing strip, etc. The production line is easy to operate, energy-efficient and cost-effective.

-

PE/PP/PET/ABS Water-cooled Strand Pelletizing Production Line

The plastic water-cooled brace granulation equipment produced by our company can be used for granulation and secondary utilization of waste plastics such as PE / PP / PET / ABS. The plastic pelletizing machine is composed of feeding system, extruder, die, screen changer, cooling water tank, drying fan, pelletizer and control system. The granulation machine’s output can range from 50kg / h to 800kg / h. This series of granulator has the advantages of stable operation, easy operation and strong continuous production capacity. The plastic particles produced have the characteristics of regular shape, uniform size and no bubbles.

-

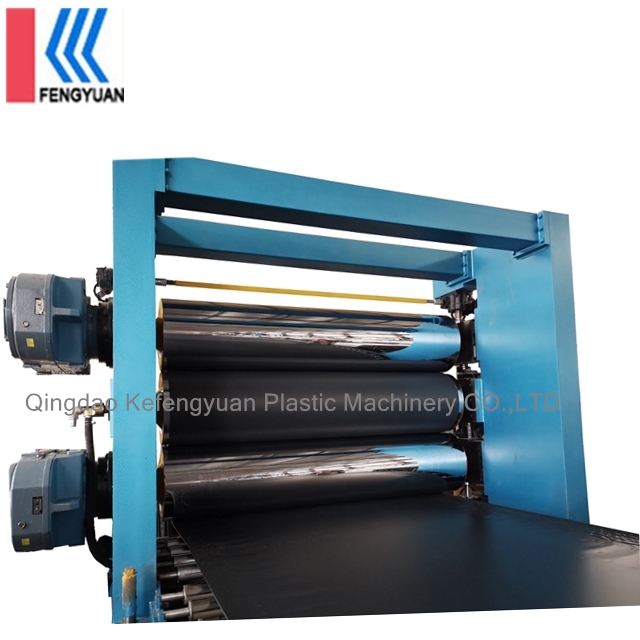

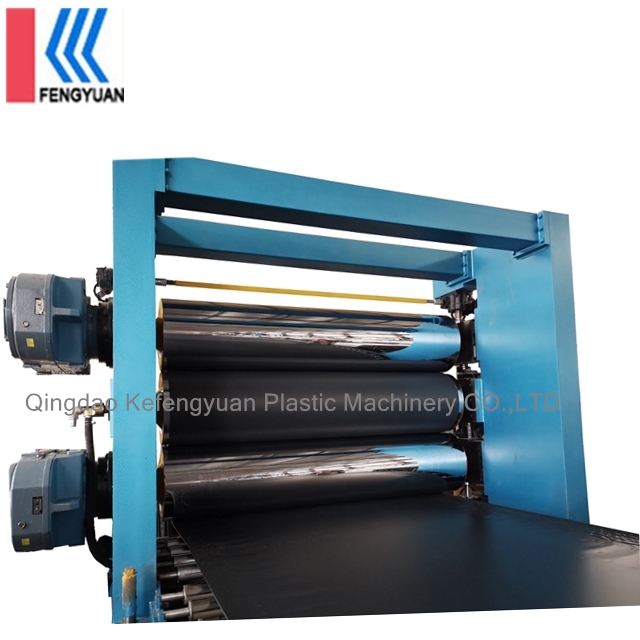

PE/PP Board/Sheet Production Line

Kefengyuan plastic board /sheet production line can be used to produce PE / PP / ABS and other plastic board and sheet products. The unit has superior design performance, high degree of automation, uniform plasticization, stable extrusion and high output. The precision calendering roller has a precise adjusting device to ensure the accurate shaping of the plate. The cutting device adopts the cutting method of opposite edge cutting and fixed length cutting to make the size of plate products accurate and unified.