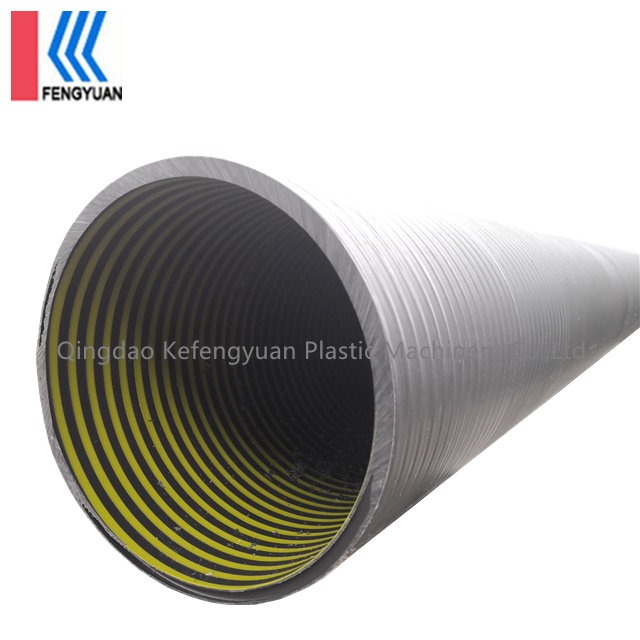

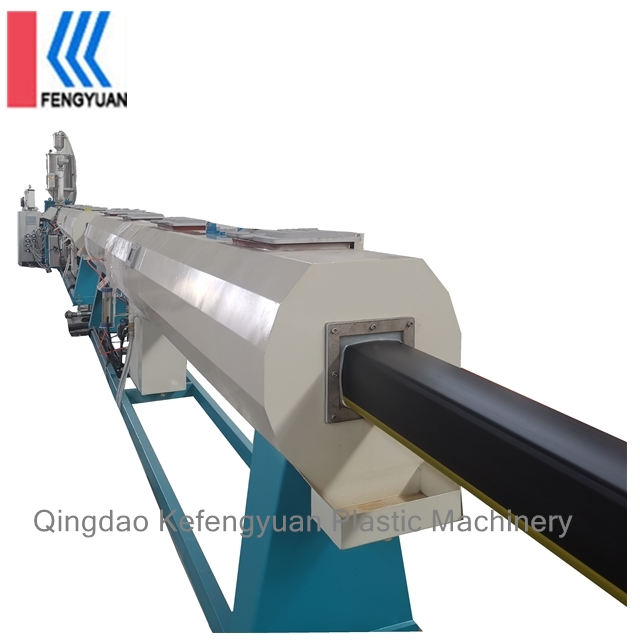

HDPE hollow wall winding pipe production line

The extrusion line is designed with advantaged technology and several patented technologies of our company have been applied. High speed and excellent extrusion quality by adopting two sets of single screw extruder with high efficiency performance. Unique design of composite die-head for large diameter winding pipe processing with high production efficiency. High quality of winding pipe produced by adopting the unique winding process. The cutting machine can choose single cutting machine or thread cutting and milling integrated machine, with good sealing and high safety factor. All parts of the production line run in perfect synchronization,easy operation and high performance by adopting an advanced PLC control system with touch LCD.

Main extruder

High efficiency single screw extruder with optimal length diameter ratio has the advantages of large output, good plasticization and long service life.

Co-extruder

It is used to produce inner coated or outer coated two-color and multi-color winding pipes to make the pipes more beautiful and durable

Extrusion Die-head

Spiral shunt structure , use steel 40Cr, With forging, quenched and tempered processing. The flow channel processing is hard chromium plating and polishing.

Vacuum tank and water cooling tank

The most scientific box design and all-round spray setting make the cooling and shaping effect reach the best.

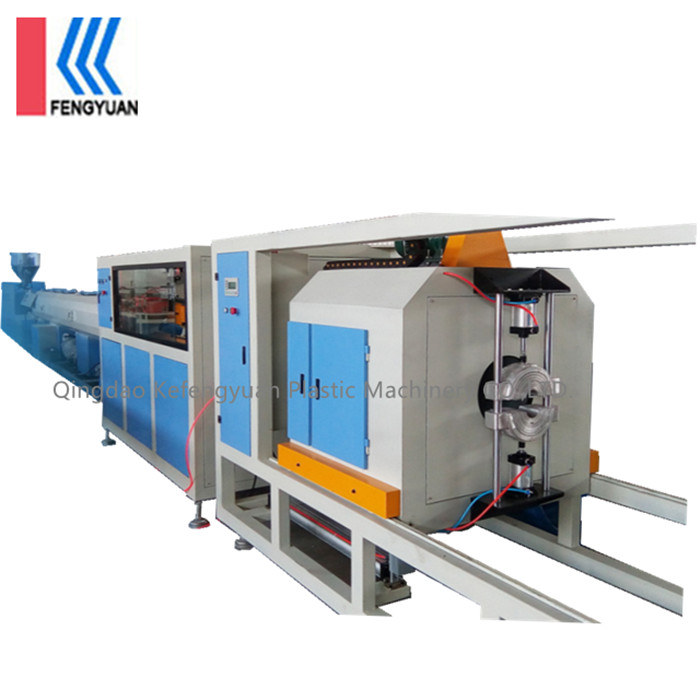

Haul-off machine

The transmission speed is controlled by programming and the track is driven by servo motor to make the operation more stable.

Winding machine

The winding machine adopts universal joint, integrated winding roller or detachable winding roller can be selected. It can be flexibly arranged according to the layout requirements of the workshop, including ladders, gluing extruders and control cabinets.

Stacker

Through electric and manual adjust switching, the adjustment is more accurate.

Electrical control system

The PLC of Siemens is used, the electrical components are Schneider and Siemens, the temperature control device is Omron, and the frequency converter is ABB and Fuji.