ABOUT US

About us

Qingdao Kefengyuan Plastic Machinery Co., Ltd., located in Qingdao (China), covers an area of 12000 square meters. The company’s area is divided into production plant (including production workshop, assembly workshop, storage workshop and quality inspection workshop), office area and living area (Personalized dormitory, restaurant, etc). It is a professional manufacturer of plastic machinery and equipment. Our products and services cover all technologies of plastic pipe, sheet, profile, strip production line and recycled plastic crushing granulation machinery.

-

-Founded in 1995

-

-24 years experience

-

-+More than 18 products

-

-square meters

application

NEWS

-

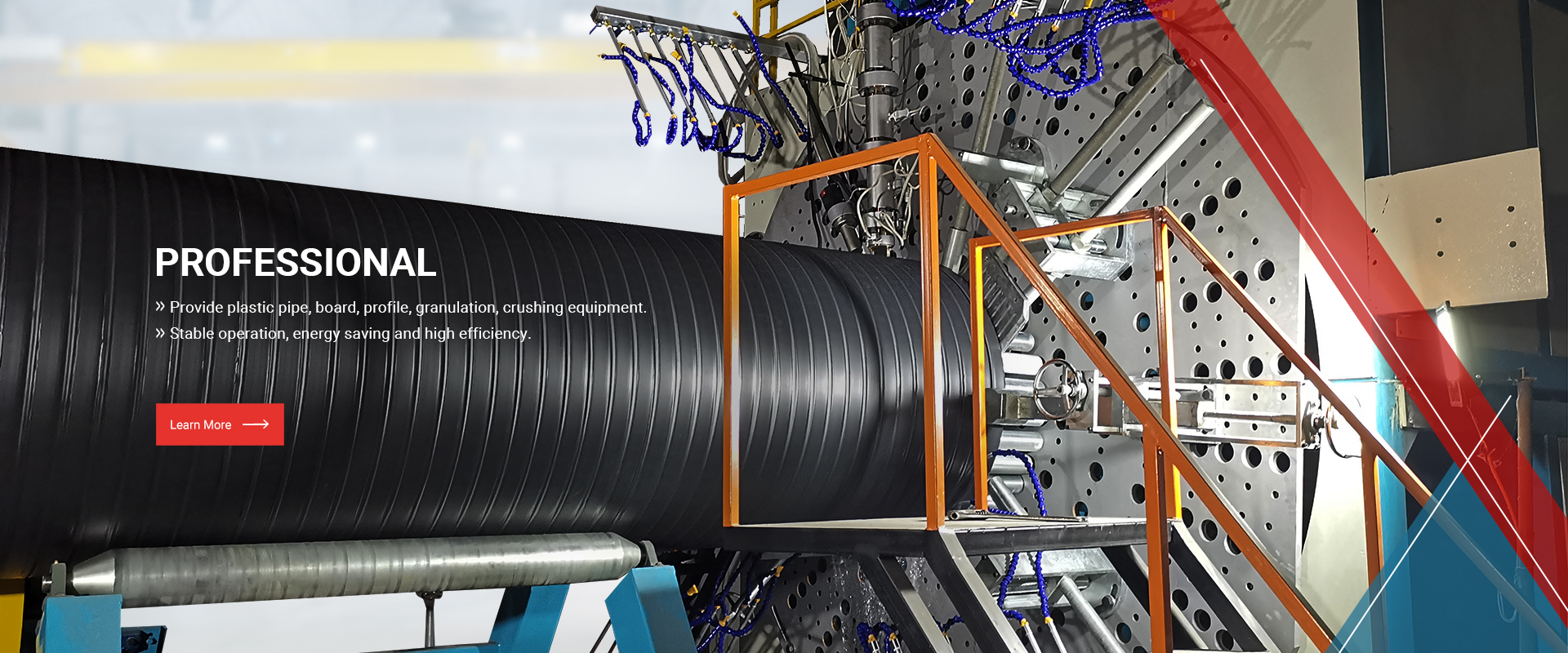

The new large-diameter hollow wall winding pipe equipment is delivered from the factory.

The 1200mm-3000mm HDPE hollow wall winding pipe production line produced by Qingdao Kefengyuan Plastic Machinery Co., Ltd. has been tested in the factory. It runs stably and all indicators meet customer requirements. After that, it will be loaded and sent to Qingdao Port today and the it will be ...

-

New Year’s Message from Qingdao Kefengyuan Plastic Machinery Co., Ltd.

With the joy of harvest and full of longing for the new year, Kefengyuan Plastic Machinery Co., Ltd. welcomes the Chinese New Year. On the occasion of saying goodbye to the old and welcoming the new, I would like to extend New Year’s greetings to all employees who have contributed to the co...