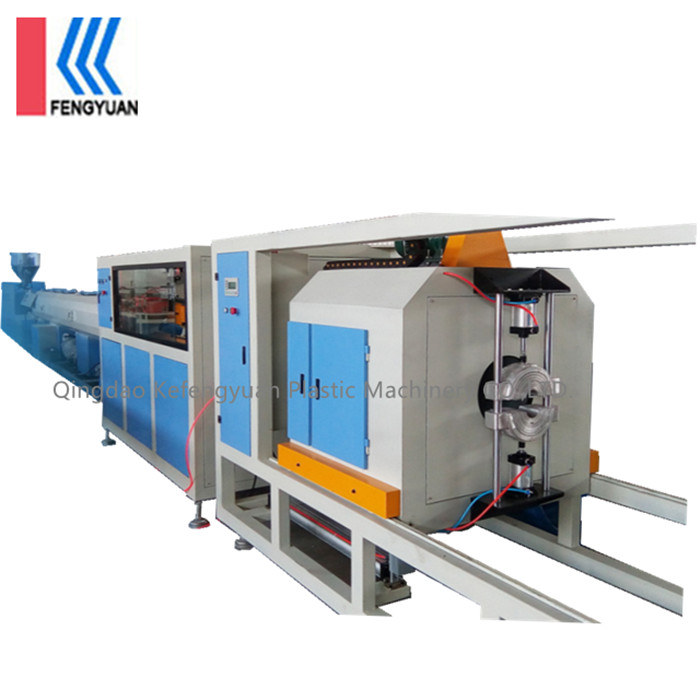

HDPE Inner Rib Enhanced Winding Pipe Production Line

HDPE inner rib enhanced winding pipe is a new type inner rib enhanced winding pipe product. Welding to make by spiral winding of inner rib enhanced profile, which has smooth inner wall and this material has the following features, corrosion resistance, light weight, easy installation, long life service(50 years). The connection of the two pipes can be thermal shrinkable sleeve connection or electric melting connection. It’s the idealized replacement of concrete, cast iron and ceramic pipes etc.

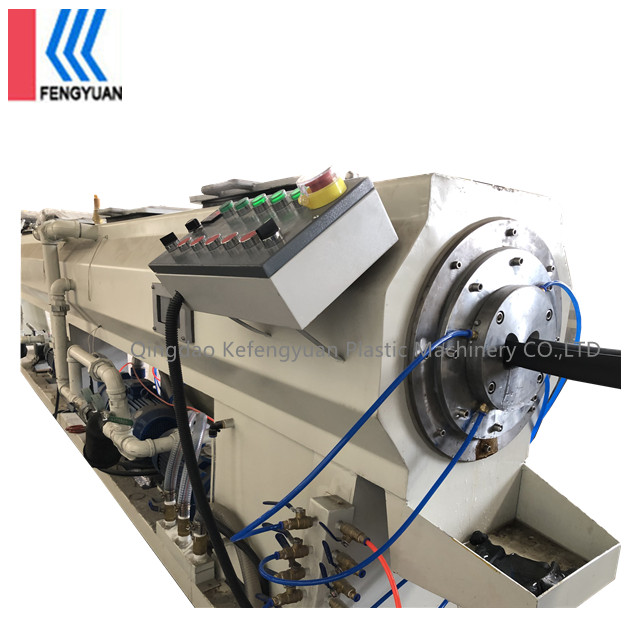

Single screw extruder

High efficiency single screw extruder, fast production speed and long service life.

Die-head

It is forged with 40Cr, the runner is plated with hard chromium and polished, and the exterior is sprayed with high temperature resistant paint.

Vacuum tank

The tank body is made of 304 stainless steel and can realize three-dimensional direction adjustment, with built-in circulating water spray cooling device, better shaping effect.

Winding machine

The machine adopts PLC control, which can be accurately synchronized with the extrusion part. Use universal joint drive, stable operation. The winding roller can choose integrated or split according to the production demand, which can be flexibly applicable to different plant layouts.

Stacker

It adopts a combination of electric adjustment and manual lead screw adjustment to make the adjustment more accurate.

Electric control box

ABB or Fuji brand frequency converter, Siemens or Schneider brand AC contactor and low voltage elements are adopted.