Pipe Extrusion Line

-

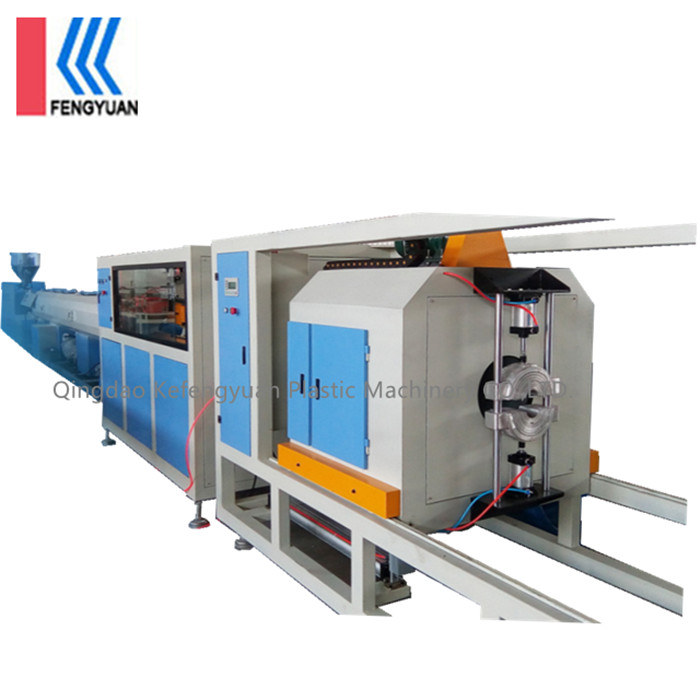

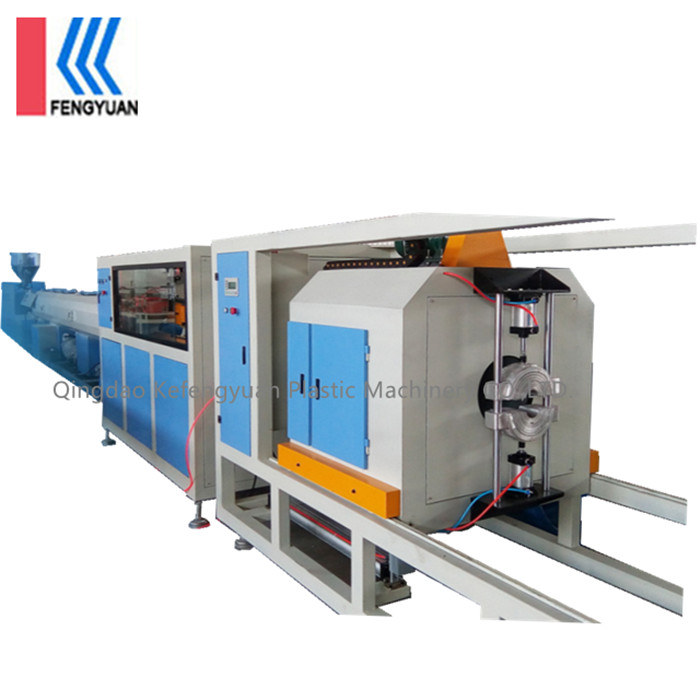

UPVC/CPVC Pipe Production Line

The PVC extrusion line produced by kefengyuan Plastic Machinery Co., Ltd. is composed of mixer, twin-screw extruder, die, vacuum cooling water tank, inkjet printer, haul-off machine, cutter, opening extending machine and bracket. We can produce large-diameter PVC production line, PVC double pipe/four pipe production line and PVC perforated pipe production line. Our equipment has the advantages of high efficiency and energy saving, stable production and high cost performance.

-

PP/PE/PA Single Wall Corrugated Pipe Extrusion Line

The production line is applicable to the production of small-diameter (9-64mm ) single wall corrugated pipe with PP / PE / PA as raw material. The production line consists of automatic feeding & drying machine, extruder, forming machine, Winding machine and electric control system. The produced single wall corrugated pipe is formed at one time through a special mold, which can be widely used in electric conduit, automobile internal line protection pipe, washing basin drain pipe, air conditioner drain pipe, farmland concealed pipe and other fields.

-

HDPE hollow wall winding pipe production line

The extrusion line is mainly for producing hollow wall winding pipe. HDPE hollowness winding pipe has small masses and a low roughness coefficient, are widely used for sewerage systems, storm drains, treatment facilities and sanitation of the old pipeline, well and various sewage tanks are manufactured. Pipes with diameters from 200mm-4000mm and the stiffness classes SN 2,4,6,8,10,12,14,16. Pipe extrusion line first produces square pipes from HDPE, then with the help of a co-extruder and spiral molding machine, spirally wound onto the walls and subsequently welded together forming the pipe body. Pipe extrusion and winding system are separately controlled, can be used separately. The line energy saving, easy to transport and installation, the investment is lower, easy to maintain.

-

HDPE Inner Rib Enhanced Winding Pipe Production Line

HDPE inner rib enhanced winding pipe production line consists of single screw extruder, automatic feeding and drying machine, profile extrusion mould, calibration mould, vacuum tank, haul-off machine, winding machine, cutting machine, stacker and electric control system etc. Advanced design, exquisite workmanship, use high effective single screw extruder, low energy consumption, high capacity, PLC intelligent control, stable and reliable and high automation. The production line can produce inner ribbed tubes with diameters from 200 mm to 3600 mm. Inner rib profiles adopt one time extrusion forming technology unique designed by our company and calibrated and cooled through calibration mould and calibration platform to form profile, which goes through winding to form the inner rib outer corrugated pipe. The equipment has the advantages of large production pipe diameter, fast production speed, sustainable and uninterrupted production and saving production cost.

-

PEPP Solid Wall Pipe High Speed Extrusion Line

The production line is an energy-saving high-speed production line newly developed by our company with advanced technology and high-efficiency single screw extruder. It is suitable for high-speed extrusion of polyolefin pipes such as HDPE and PP. Compared with the ordinary production line, the production speed and efficiency have been significantly improved. The production line can produce single-layer or multi-layer solid wall pipes with pipe diameter ranging from 16mm to 3000mm. The produced pipes have the advantages of high temperature resistance, aging resistance, high mechanical strength, environmental stress crack resistance and strong creep resistance. They can be used as water supply / drainage pipes, gas pipes and power pipes.

The production line’s unit comprises extruder, co-extruder, pipe die-head, vacuum cooling water tanks, haul-off machine, cutting machine, stacker etc. All units are centrally controlled and coordinated by computer, which has the advantages of high degree of automation, stable and reliable production, high efficiency and energy saving.