PP/PE/PA Single Wall Corrugated Pipe Extrusion Line

The production line is applicable to the production of small-diameter (9-64mm ) single wall corrugated pipe with PP / PE / PA as raw material. The production line consists of automatic feeding & drying machine, extruder, forming machine, Winding machine and electric control system. The produced single wall corrugated pipe is formed at one time through a special mold, through the gear transmission module and high-precision setting template, the equipment makes the joints of the formed bellows free of dislocation, ensuring the strength of the pipe and the smoothness and beauty of the inner and outer walls. The formwork is cooled by water, and the module is air-cooled, so that the forming speed of the produced bellows is fast and stable, and the maximum production speed can reach 30 meters per minute. The single wall bellows produced by the equipment has the characteristics of high temperature resistance, corrosion resistance, wear resistance, high strength and good flexibility, which can be widely used in electric conduit, automobile internal line protection pipe, washing basin drain pipe, air conditioner drain pipe, farmland concealed pipe and other fields. We can provide suitable single wall bellows equipment according to the needs of customers, and we can also customize special machines according to the shape and size of bellows samples

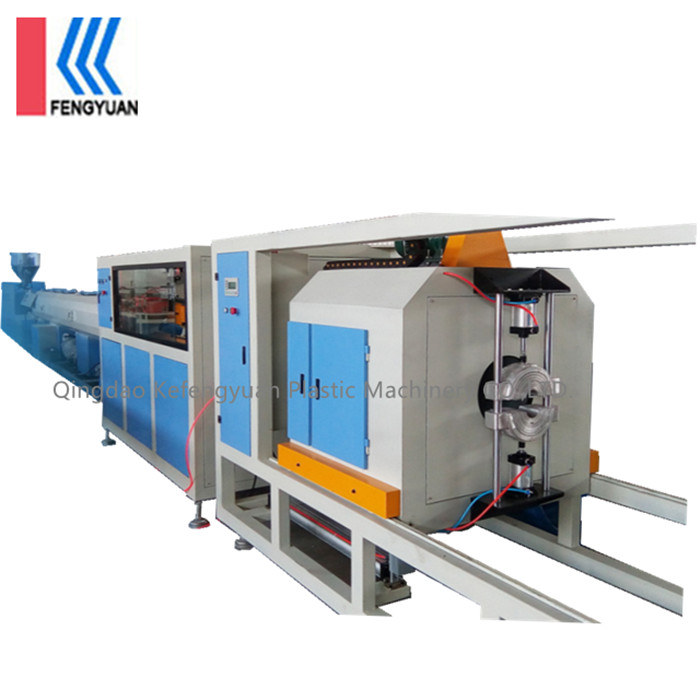

Extruder and Molding machine

The extruder is a high-efficiency single screw extruder with automatic feeding and drying machine. The molding machine has reasonable layout and stable operation, with automatic lubrication system, and the production speed can reach 20-30 meters per minute.

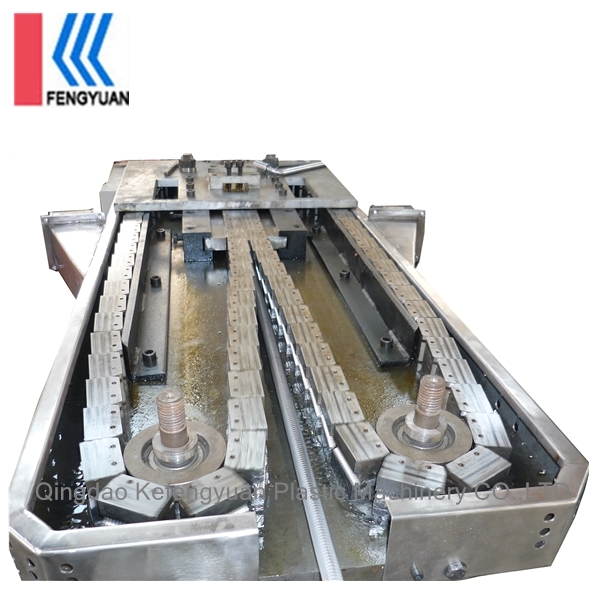

Forming molds

The molding molds are made of special materials, with nitrated surface and double cavity design, has the advantages of long service life, smooth and delicate appearance of the pipe wall and clear and uniform ripple.

Winding machine

Automatic control, single station or double station winder can be selected according to production requirements, and the winding size can be freely selected.

Electrical control system

PLC control or traditional console control can be selected according to user needs.