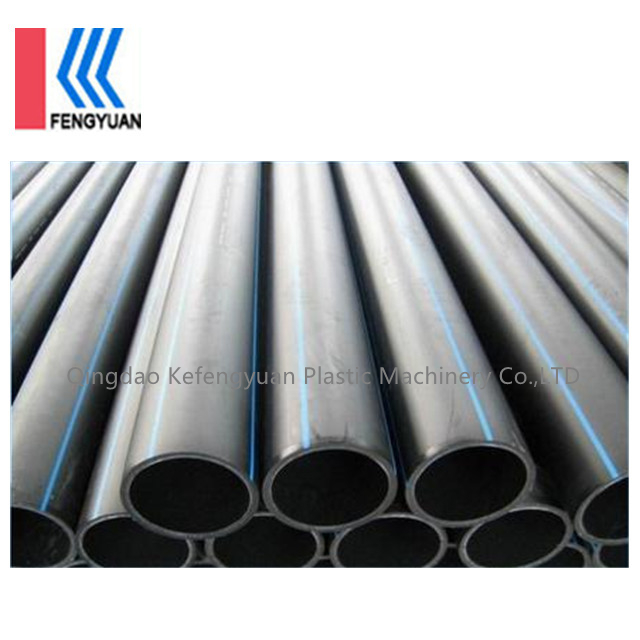

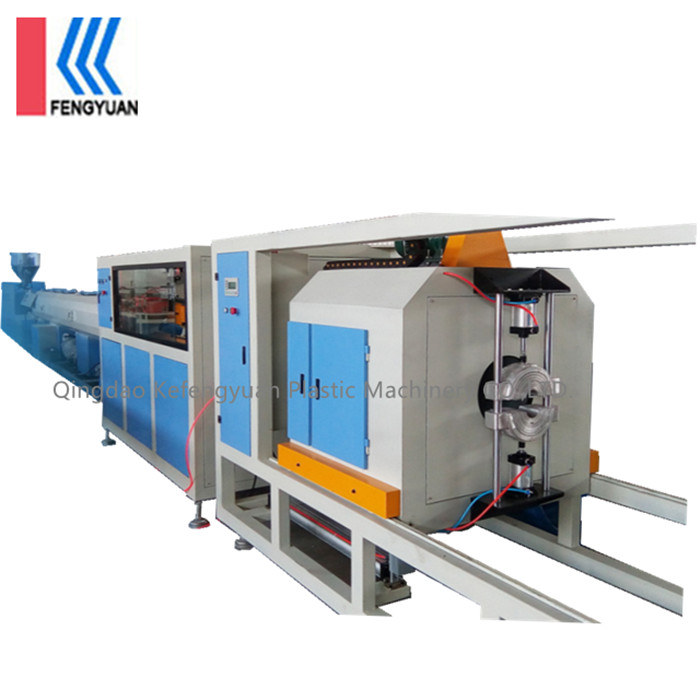

PEPP Solid Wall Pipe High Speed Extrusion Line

High speed single screw extruder

High efficiency extruder is designed for HDPE/PP pipe, equipped with reducer which is high speed and low noise, feeding section with cooling unit and reversing spiral groove, different pitch undulant screw which allows great output, lower melting temperature, and lower energy consumption.

Extrusion Die-head

Distributed spiral composite extrusion die-head ensures the melting pressure and flux even and stable, the surface of pipe smooth and glossy.

Vacuum calibration tank and Spray water cooling tank

Advanced pipe line layout design and adjustable spray angle for better cooling effect.

Haul-off machine

For different pipe diameters and production speeds we adopts 2-claw/3-claw/4-claw/6-claw/8-claw/12-claw type unit, Traction power unit with separate motor or servo motor.

Cutting machine

Dust-free cutting machine ,can efficiently cuts tubes of all sizes and thicknesses.

Stacker

Small diameter use winding machine. Large diameter pipe used stacker.

Electrical control system

The PLC of Siemens is used, the electrical components are Schneider and Siemens, the temperature control device is Omron, and the frequency converter is ABB and Fuji.