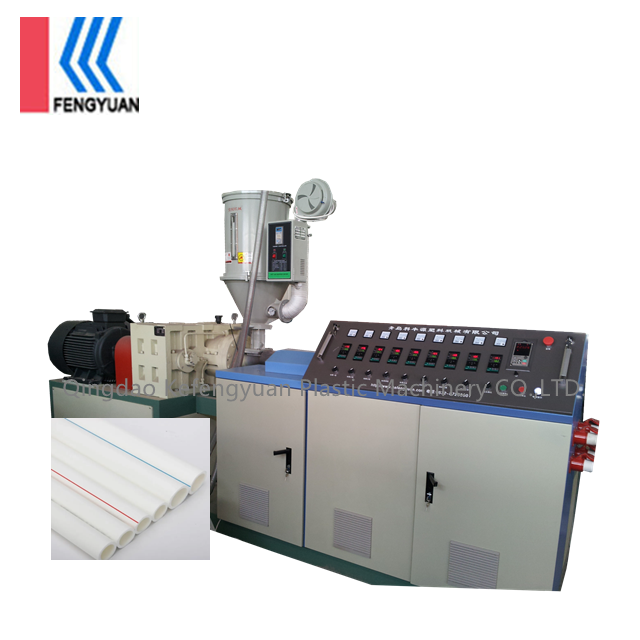

PPR/PE-RT Pipe Production Line

Extruder

According to the characteristics of PP-R / PE-RT, the high-efficiency single screw extruder produced by our company is adopted, equipped with unequal distance corrugated screw, forced cooling reverse spiral groove feeding section, and equipped with high-speed low-noise hard tooth reducer, which has the advantages of large extrusion capacity, low melting temperature and good energy-saving effect.

Die-head and mould

The split screw head is adopted to ensure uniform pressure and flow without fluctuation, so that the pipe’s structure is dense, the surface is smooth and there is no flow mark. The mould is forged with special alloy, with high accuracy and long service life.

Haul-off machine

The upper and lower crawler tractor can be of open or closed layout. Variable frequency speed regulation can perfectly match the production speed.

Vacuum tank

Special sizing sleeve is adopted to ensure accurate sizing. The tank is made of stainless steel and equipped with conical spray device inside, which has good cooling effect and high efficiency.

Winder

Double position winder, stable operation and easy operation.

Electric control system

Siemens or Schneider electrical components and control switches, abb or Fuji frequency converters are adopted. Console or Siemens PLC control system, flexible and convenient operation.