Wholesale Plastic Pipe Machine Factory – Plastic/Wood/Rubber Crushing Line – Kefengyua

Wholesale Plastic Pipe Machine Factory – Plastic/Wood/Rubber Crushing Line – Kefengyua Detail:

Kefengyuan company’s crushing line is composed of shredder, conveyor belt, crusher, air suction storage bin and electric control system. The crushing unit first smashes the large materials into small pieces by the shredder, and then enters the crusher through the conveyor belt to continue crushing into smaller particles. The crushing equipment can be used to crush waste plastics, rubber, wood plastic products, etc. The maximum crushing efficiency can reach 1500 kg / h. It has the characteristics of simple operation and stable operation, which can effectively save labor cost.

We have more than 20 years of manufacturing experience in plastic crushing equipment. Each plastic crushing production line will undergo strict testing before leaving the factory. Customers can choose to come to the factory for acceptance in person or send samples to be crushed, and then we will broadcast the video live or record the crushing test video until the equipment is running correctly. Before delivery, we will use transparent plastic film coating, wooden box storage or wooden bottom to strengthen the packaging according to different machine parts. Spare parts of some important parts will also be shipped with the equipment.

The crushing unit

Corresponding models of shredder and crusher can be selected according to production requirements.

Shredder

The model of shredder ranges from 600 to 1300, which can meet the production requirements of various output. Each shredder is equipped with a ladder and platform to facilitate feeding.

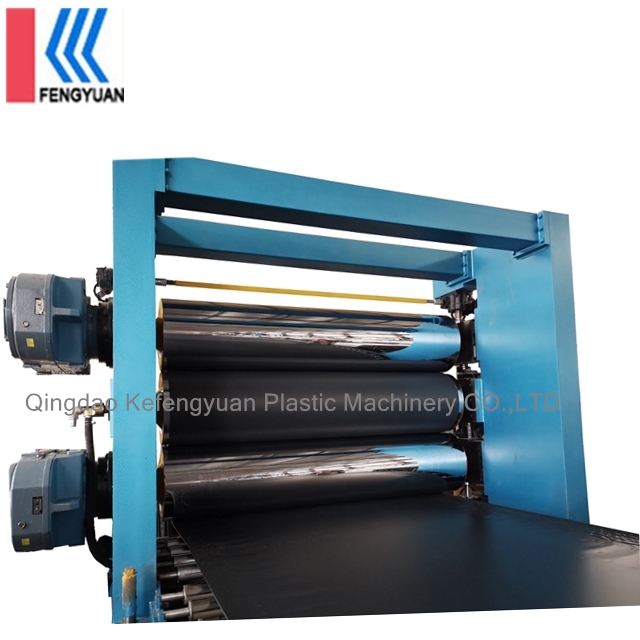

Crusher

The crusher model can be perfectly matched with the shredder. The feeding angle is specially designed to adapt to the angle of the conveyor belt and will not cause material leakage. At the same time, the appropriate screen diameter can be selected according to the particle size required for production.

Electric control system

The control cabinet is controlled by Siemens intelligent touch screen with optional language.

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Provider is supreme, Name is first", and will sincerely create and share success with all clientele for Wholesale Plastic Pipe Machine Factory – Plastic/Wood/Rubber Crushing Line – Kefengyua , The product will supply to all over the world, such as: Ukraine, Sri Lanka, San Diego, We have exported our products all over the world, especially the USA and European countries. Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products, please don't hesitate to contact us. We will try our best to meet your needs.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!