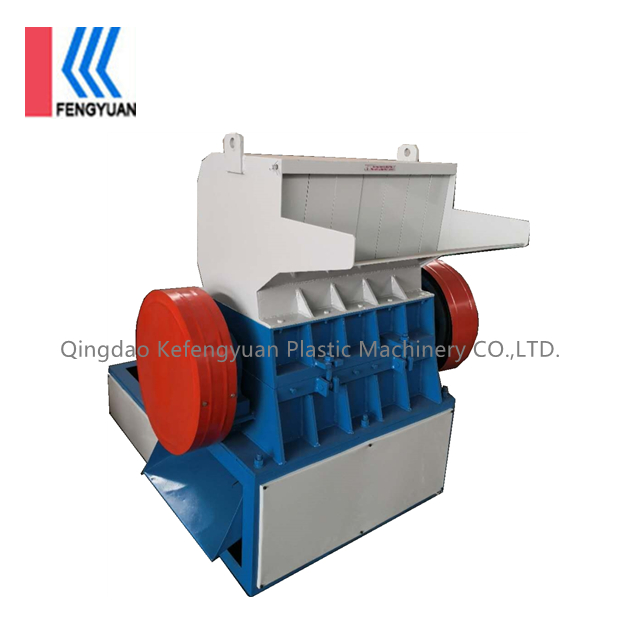

Plastic Shredder Manufacturers – PE/PP/PET/ABS Water-cooled Strand Pelletizing Production Line – Kefengyua

Plastic Shredder Manufacturers – PE/PP/PET/ABS Water-cooled Strand Pelletizing Production Line – Kefengyua Detail:

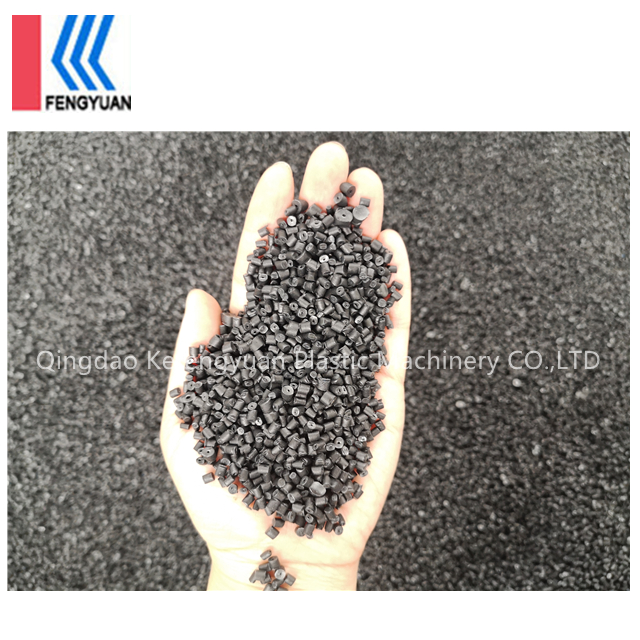

The plastic water-cooled brace granulation equipment produced by our company can be used for granulation and secondary utilization of waste plastics such as PE / PP / PET / ABS. The plastic pelletizing machine is composed of feeding system, extruder, die, screen changer, cooling water tank, drying fan, pelletizer and control system. After the melt is extruded from the small hole of the die, many hot plastic strips are formed, and then enter the cooling water tank. After the plastic strips are cooled, the moisture is removed by the drying fan, and then enter the pelletizer to cut into cylindrical plastic particles with a length of 1-5mm. The granulation machine’s output can range from 50kg / h to 800kg / h. This series of granulator has the advantages of stable operation, easy operation, hard to break strip and strong continuous production capacity. The plastic particles produced have the characteristics of regular shape, uniform size and no bubbles.

Extruder

High efficiency single screw extruder has stable output. The screw and barrel adopts wear-resistant alloy and has long service life. At the same time with degassing stage, which can effectively discharge the water vapor in the raw material and make the extruded plastic more uniform and bubble free.

Screen changer

It includes two screens and one spare screen. It adopts hydraulic propulsion, which can realize the screen change operation at the same time of production without stopping the machine.

Die-head and mould

The high-precision die is perfectly adapted to the machine head, which is convenient to replace and easy to adjust.

Drying fan

It can be set flexibly, which can effectively remove the moisture on the plastic and keep the product dry.

Pelletizer

The automatic pelletizer has stable operation and high safety.

Electric control system

PLC control or traditional console control can be selected according to production requirements.

Product detail pictures:

Related Product Guide:

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for Plastic Shredder Manufacturers – PE/PP/PET/ABS Water-cooled Strand Pelletizing Production Line – Kefengyua , The product will supply to all over the world, such as: Canada, Slovenia, Nepal, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner for you!

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.