Pe Granulation Line Factory – Plastic Water-Loop Granulation Line – Kefengyua

Pe Granulation Line Factory – Plastic Water-Loop Granulation Line – Kefengyua Detail:

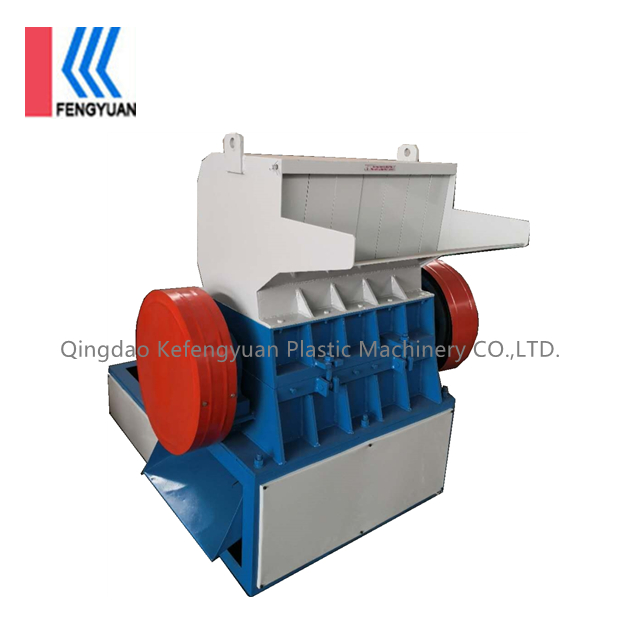

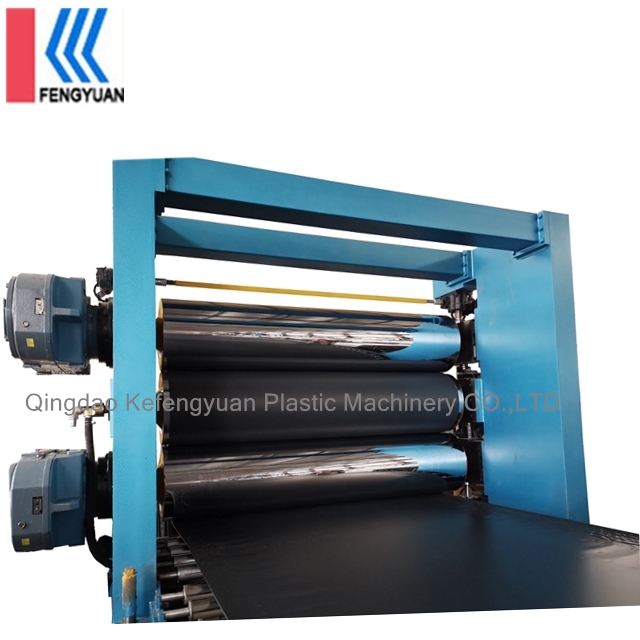

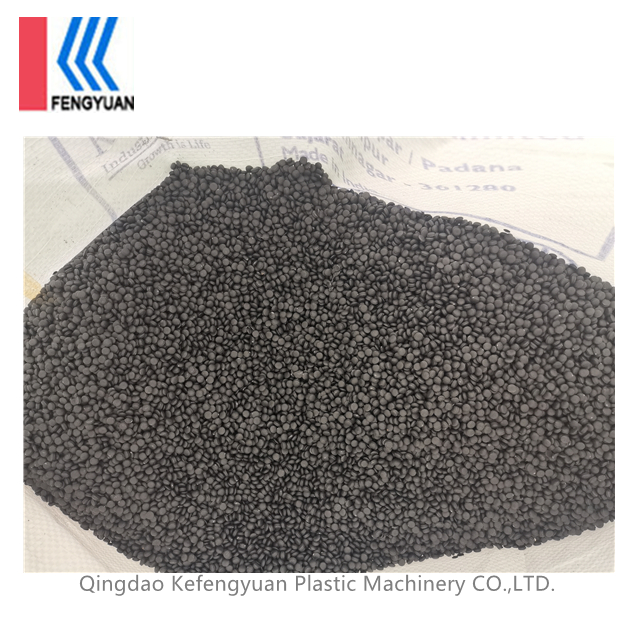

The plastic water-loop granulation equipment produced by Kefengyuan company is composed of feeder, extruder, die head, screen changer, pelletizer, centrifugal pellet dryer, vibration sieve, air suction storage bin and electric control system. The granulator can be applied to the granulation of HDPE / LDPE / PP / PET / PA and other plastics, and the output can reach 200-1200kg / h. Kefengyuan’s water loop granulation line is equipped with a quick filter screen replacement device and an automatic temperature control system. The pelletizer adopts a speed regulating motor, which can be perfectly synchronized with the extrusion speed of the extruder. According to the different granulation raw materials, the plastic crusher or plastic film agglomerator can be selected. In the production process, the labor of repeated turnover and transportation of raw materials is saved. The equipment has high output, low energy consumption, low working intensity of workers and good recycling and granulation quality, is an ideal equipment for plastic granulation. At the same time of high output, the plastic particles produced have beautiful appearance, uniform size and are not easy to adhere.

Extruder

High efficiency single screw extruder with degassing stage can ensure that the extruded material is uniform and free of bubbles. The head body is made of special alloy steel, with high precision and long service life. The hydraulic screen changer can change the screen quickly without stopping production.

Pelletizer

The symmetrical cutter can cut particles evenly and neatly, and the built-in elastic device can make the blade not easy to wear.

Centrifugal pellet dryer

The machine has good water removal performance, large treatment capacity, good sealing and convenient maintenance.

Vibration sieve

High quality damping spring is adopted, with low noise and long service life. The screen has high screening accuracy and strong self-cleaning, which can effectively solve the screening problem of strong adsorption and light specific gravity of particles.

Product detail pictures:

Related Product Guide:

Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for Pe Granulation Line Factory – Plastic Water-Loop Granulation Line – Kefengyua , The product will supply to all over the world, such as: Porto, Portland, Ukraine, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.